Subscribe to Airspeed through iTunes or your favorite other podcatcher.

These are the show notes to an audio episode. You can listen online right here by clicking: http://media.libsyn.com/media/airspeed/AirspeedDC-3Summary.mp3.

There’s also a summary post with links to all of the blog posts and episodes that covered this type rating experience at http://airspeedonline.blogspot.com/2008/05/dc-3-type-rating-whole-thing.html.

What’s general aviation really about? What’s at the core of this vocation or avocation that latches onto people like you and me and causes us to devote our time, energy, and money to it?

For some, it’s the challenge. This stuff isn’t easy. If it was, everyone would do it. Even the simplest and most straightforward aircraft require patience, skill, and diligence to fly. And even the best pilots can find new ground to break in GA.

For others, it’s the camaraderie. How do you know if there’s a pilot in the room? They’ll tell you. Pilots as a group are some of the most social creatures on the planet. They’ll travel great distances, run up massive mobile phone bills, fry Internet connections, and spend hours at the airport even while their aircraft are down for an annual or an avionics upgrade just to hangar-fly. In no other group have I experienced such a shared consciousness.

And such a universal decency. Go ahead and leave your cell phone on the shelf outside the shower building at Camp Scholler to charge while you’re running to the store and back. It’ll be there when you get back.

For still others, it’s a part of history. A part of the relatively short 100 or so years and our last couple of generations that is singular in marking the progress of technology and inspiration. No togas or pyramids or aqueducts or three-cornered hats in this history. The sweat of its brow is still wet and there’s more where that came from.

And it’s what I call the Big Dream. The elements of aviation that transcend every day life. At the beginning, it’s flight itself. Flight of any kind. The sheer wonder that a Cessna 150 can and does levitate off the ground and take you places. For some, including me, that would be enough even if there was nothing more.

But there’s more. A lot more. There are balloons and powered lift aircraft and airplanes that float and warbirds and aerobatic airplanes and rotorcraft . . . You get the idea.

The Big Dream is about pushing yourself. Identifying places where your reach exceeds your grasp and then committing to tackle those things.

I had finished my instrument rating in October and was just beginning to think about what to do next when I heard an interview on Aero-News’s special feature. I’m a regular listener to Aero-News and other aviation podcasts, but I rarely listen to the special features. But the title of this one caught my eye, so I downloaded it and listened to it.

[Aero-News outtake]

A few weeks later, I called up Dan and had him on Airspeed, both because I thought that the audience would enjoy hearing him and because I personally wanted to ask a few additional questions.

At the time, I held a private pilot certificate with Airplane Single-Engine Land and Instrument Airplane ratings. About 185 hours total, 86 hours pilot in command, 16 hours of actual IMC, 110 actual or simulated instrument approaches, and 380 takeoffs and landings. I had no complex, no high-performance, and no multi time unless you count the Otter rides with Dave Schwartz and a couple of other experiences.

Thinking back, one could be forgiven for wondering what I was thinking. Technically, all one needs to qualify for the DC-3 SIC training is a private pilot certificate with a multi-engine rating. But, as many aviators know, there tends to be a big difference between what one is legally qualified to do and what is smart to do.

Dan is a qualified and seasoned instructor and airline pilot and has done a lot of training in the DC-3. I wasn’t worried about safety. But I no real means by which to gage how I’d handle the increased complexity of something like the DC-3. I gave it a lot of thought and the trepidation about complexity gradually flowed into that category marked “challenge” under the heading, “Big Dream.” When enough piled up in that category and I had checked the savings account to make sure that I could swing it, I decided that the DC-3 type rating would be the very thing for the next challenge.

So, during a phone update from Sun ‘N Fun in April for the show, I went ahead and committed.

[I’m In Audio]

Six or seven weeks later, I was on a Delta flight to Atlanta.

Prior to leaving, I had downloaded and studied the flight training and ground training manuals from Dan’s website. The DC-3 is about 62 feet long, has a wingspan of about 95 feet, and the highest point on the fuselage is about 17 feet off the ground when parked. The tip of the tail is about 23 feet off the ground when the tail is flying. It has a 1,200 hp Pratt & Whitney 1830-92 engine on each wing. It masses about 18,000 lbs empty and has a max gross of about 25,000 lbs. It cruises at 130 KIAS and has a Vne of 206 KIAS. It will carry more than 800 gallons of fuel and each engine oil talk holds nearly 30 gallons of oil. And, gloriously, it’s a taildragger.

The particular DC-3 that I flew is Serial No. 2054, manufactured in 1937 or 1938 and owned by Gryder Networks. She started out flying for Swiss Air with tail number HB-IRO. She then made her way back to the US, got the tail number she bears today, N134D, and flew for Ozark Airlines until 1974, by which time she was converted to fly freight. Dan bought her a few years ago and has been doing training and airshows with her ever since. She’s named “Darla Dee,” after Dan’s wife, which proves Dan’s good sense.

Dan has only flown the airplane from the left seat twice. He prefers to fly from the right seat with a trainee, sponsor, media rider, or dreamer in the left seat.

On April 1, 2005, the ‘three suffered a catastrophic failure of the drag strut linkage of the right main gear on landing at Thomaston, Georgia, causing the aircraft to come down on her right wing, causing damage to an engine, prop, gear, tire, oil cooler, right wing tip, and the

center section of the right wing. But, 27 weeks later, she flew again after two complete engine changes, more than 2,600 hours of labor, and almost 2,500 new rivets.

Around that time, Herpa Miniature Models became involved. Herpa is a German company that makes very accurate and detailed die-cast models of aircraft and civilian and military vehicles, as well as lighting and scenery. Herpa sponsoded the ‘three and put the set of red and white appliqués on her that you can see today. Interestingly, I think the design scheme for the actual airplane came from a Herpa model – probably the first time that that’s happened. Even before I went to Griffin, I bought a 1:200 scale and had it on my credenza. Dan likes to say that he flies the 1:1 scale.

The class assembled in Griffin that night to get a first look at the airplane, get the welcome part of the ground school, and head out to dinner. We had four people in the class. Tom is a former San Francisco cop who then flew for the airlines for ten years. He continues to serve as a flight instructor in California and he was already type rated in the ‘three. This was recurrent training for Tom. Roland and Gerrit came all the way from Germany. Roland is an engineer by training who does sales around the world. Gerrit is an orthopedic surgeon. I believe that both Roland and Gerrit have commercial certificates. Roland even had a couple of transatlantic crossings in his logbook. Roland and Gerrit each had at least five (and more likely ten) years on me in age and Tom might have had 20. It was apparent that I was the pup of the group in terms of both age and aviation experience.

Training started in earnest the next day. We divided into two teams of two with one team completing the interior preflight and the other doing the exterior preflight and then the team switch and repeat the process. The preflights were a great opportunity to get to know the aircraft a little better. The first interior preflight had me still mystified about the function of maybe a third of the systems, but at least I figured out where everything was. I figured out pretty quickly that it was going to take a few more times before I began to feel comfortable with the systems.

The first exterior preflight was even more educational. The DC-3 is an all-metal airframe, but the control surfaces are fabric. They’re also interchangeable to some extent. If you look at the elevators, you’ll see that you could flip one over and install it on the other side with no problem.

The other thing is that the flaps cover not only a good portion of the length of the wings, but continue all the way across under the fuselage. Wasn’t expecting that. But it stands to reason. The ‘three comes over the fence at a speed not unlike that of a Cessna 172. It’s noted for its short-field capabilities and that extra flap area helps in that regard.

I was third to fly the first day. I sat down at the controls, got buckled in, and settled in to fly. Dan let me do a few turns, climbs, and descents to get the feel of the aircraft. It handled mostly like a big Apache. Except that the ailerons are mostly useless, so you turn with rudder and follow that with aileron appropriate to the turn. And not too much aileron. Then we entered the pattern for runway 30 at Thomaston – Upson County Airport (KOPN).

Here’s audio from a landing on my first flight. And a bit of a lecture from right after landing. As a light aircraft driver, I’m used to giving the airplane full power on takeoff so, when Dan told me to add power for takeoff, I pushed the throttles toward the firewall. Although the engines can do 48” of manifold pressure and 2,700 RPM for 1,200 hp, they’ll self-destruct after more than about a minute at that setting. Great for dodging shopping centers with a real V1 engine failure, but not so great when you have two good motors and want to use the airplane again the next day. We used “maximum except takeoff” or “METO” power of 42” and 2,550 RPM, which yields about 1,050 hp. In pushing up the power, I was unconsciously heading for maximum instead of METO power.

[Flight Audio 01]

On the second flight, we rotated pilots but ended up in an odd downwind by the time the personnel switch was complete. I was also fumbling a little with the callouts because I wasn’t sure where we were in the litany of the pattern. I started on the assumption that we were at the beginning of the downwind and was going to call out everything beginning with the approach checklist, but Dan figured out pretty quickly that we needed to hit the reset button on this trip around the patch. So I got a treat. A high-speed pass down the runway. 160 knots gear up and 50 feet off the deck in a 22,000 pound airliner.

Here’s the audio beginning with the confusion and ending with the low pass.

[Flight Audio 02]

A couple of things. First, Dan’s observation about people pulling over to watch you land is absolutely true. You arrive at Thomaston or a similar airport and start flying the pattern. By the third time around or so, there’s usually a little gathering of cars and pickup trucks pulled over by the side of the road just short of the approach end of the runway and there are people standing around watching you. That just doesn’t happen in a Cessna 172.

Second, you heard the commentary from the other guys back in the jumpseat and in the hallway behind the cockpit. Although the guys who aren’t flying are usually pretty quiet and are watching you and going through the callouts silently in parallel, there’s no doubt that this is a collaborative experience. When someone nails a landing or does something well or noteworthy, there’s encouragement, congratulations, and the occasional verbal high five. I think that the ‘three is rare or singular in this respect. If it were smaller, you wouldn’t have three or four guys looking over your shoulder. If it were larger or newer, there’d probably be a simulator for it and the other guys would be in a classroom or on break waiting for their rotations instead of actually in the plane and flying with you. Add another aspect to the magic of the DC-3.

Second, you heard the commentary from the other guys back in the jumpseat and in the hallway behind the cockpit. Although the guys who aren’t flying are usually pretty quiet and are watching you and going through the callouts silently in parallel, there’s no doubt that this is a collaborative experience. When someone nails a landing or does something well or noteworthy, there’s encouragement, congratulations, and the occasional verbal high five. I think that the ‘three is rare or singular in this respect. If it were smaller, you wouldn’t have three or four guys looking over your shoulder. If it were larger or newer, there’d probably be a simulator for it and the other guys would be in a classroom or on break waiting for their rotations instead of actually in the plane and flying with you. Add another aspect to the magic of the DC-3.

We get another touch and go in on 30 and then, on the turn from crosswind to downwind, Dan gives me a little demonstration of the respective roles of the rudder and aileron in this airplane. It’s really true. You drive it with your feet and the ailerons follow.

[Flight Audio 03]

By the way, I’m a fan of describing yourself at an uncontrolled airport by the appearance of the aircraft as opposed to tail number unless there’s another similar-appearing aircraft in the pattern – in which case you revert to your tail number. I flew with a guy recently who objected pretty strenuously to my doing that on the theory that another similar aircraft could appear in the pattern at any time. I’m not busting his chops here, but I think that, unless you’re at Oshkosh in July, the chances are pretty thin that another DC-3 will be sharing the pattern with you. I delighted in making the calls that “The DC-3 is turning left base.”

Here’s an example from the second flight on the first day. We’re on final a half mile out when an RV-4 calls from the marker. We’re turning inside of him. N143D might not mean anything to anyone not local, but “DC-3” sure does.

[Flight Audio 04]

I’m also a fan of the most of the unofficial chatter that you get at some uncontrolled airports. And some controlled ones. As long as safety or important communications aren’t compromised, I have no problem with nontraditional commentary. About halfway into the first flight (unfortunately during a time when the recorder wasn’t working), a Cessna 172 announced that it was on final for the parallel grass landing area at Thomaston while we were turning base. I was a little too busy at that moment to look for the traffic but, by the time we were on final, the 172 made another call to say that he was touch and go off the grass.

I spotted him coming off the froghair to the left of the pavement, keyed the mic, and made a call I’ve been wanting to make since I first heard it on Will Hawkins’ show, The Pilot’s Flight Podlog: “Guns! Guns! Guns! The DC-3 has the Cessna traffic!”

I resisted the urge to add a Rod Machado-esque “. . . and I’m gonna eat ya, little buddy!” Barely.

Later in the flight, I had the chance to land her to a full stop. It’s basically the same as the touch and go except, obviously, that you don’t throttle back up, and you keep the tail flying behind you as you roll out and then set it down. The tail is amazingly light in the three as we flew her. We carried a 55-gallon drum of water in the tail storage area for ballast and it was still darned light. Almost all landings in the DC-3 are wheel landings where you put the mains down first and then set the tail down. You can do a three-point landing in the DC-3, but you run the risk of having the tail oscillate, which could ultimately lead to a nose-over and nose and prop strike. So SOP is to do a wheel landing and make sure that the horizontal stabilizer is just about done producing lift before you let it down. Here’s audio from my last landing of the second flight.

[Flight Audio 06]

The training was full of firsts, but a couple of things in particular stick in my mind.

First, although this is very sophisticated and technical CRM-based training in an airliner, you do it all below about 3,000 feet MSL, or about 2,000 AGL. And you’re rarely going more than 130 KIAS. You fly with the windows open and, if you’re not busy with the throttles or other stuff with your right hand, you can fly with your right hand while sticking your elbow out the window and resting your forearm on the windowsill. It’s stately and genteel like that as you watch the Georgia countryside slip beneath your wings.

The other thing is this. Dan pointed out on the second or third trip around the pattern that people were pulling off the road at the approach end of the runway to watch us land. And it was true. That’s never happened to me before and it was an amazing feeling.

We finished up the flight at Griffin and put the airplane to bed. Dan’s been talking about his DC-3 simulator for a day or so now. Here’s a little outtake after one of my better trips around the pattern on the second flight of the first day.

[Flight Audio 05]

It’s gotten us all wondering. One of the reasons that Dan was able to buy the ‘three and do the initial contract training that helped to pay for it was that there’s no such thing as a DC-3 simulator. At least not a certified flight training device. As for me, I figured that he had MS Flight Simulator on a larger screen with a surplus DC-3 pilot seat in front of it.

So he gets us all piled into one of the crew cars and puts Gerrit in the driver’s seat. Dan is, of course, in the right seat. Dan says, “put it in drive and take your foot off the brake and let her creep forward.” Gerrit does this.

“Okay, say ‘Set power.’”

There’s a moment of hesitation, and then Gerrit says, “Set power.”

Dan responds by saying “Power set” and then flashing two fingers in front of Gerrit and saying “V2.”

Gerrit hesitates a moment, but says “Gear up, climb power, after-takeoff checklist.”

The row of hangars is about 250 feet long with pavement all the way around. Gerrit makes a left and we’re suddenly on the crosswind leg of a traffic pattern. At the next corner, Gerrit says “Cruise power, cruise checklist” and Dan gives the correct responses.

It goes like this the rest of the way around the hangar through downwind, base, and final, except that Gerrit gets a little behind the car and arrives at the runway threshold with only half flaps.

Another time around. A little better, although it’s apparent that you have to think quickly to get everything done on the “downwind” while moving at five miles per hour.

We got four times around the patch in Dan’s simulator before we turned to head out for dinner.

I got back to the hangar around 11:00 and did a pretty extensive blog entry and did another episode of the show and posted it. Even though the crew quarters had every amenity that one could want, including high-speed internet, it was about 2:00 a.m. before I had the episode fully written, edited, recorded, and posted. I was beat.

The next morning, we did ground school again until about noon. Dan had said in an e-mail prior to our arrival that a reporter from Plane & Pilot would likely be joining us that day to ride along and experience the training firsthand with the group. At about 11:00, he pulled up in his Mooney and, to my surprise, it was none other than James Wynbrandt, polymath author, musician, and sometime denizen of the virtual hangar on the very popular and authoritative podcast, Uncontrolled Airspace. I had met James briefly at Oshkosh during Podapalooza 2007 and had heard his UCAP appearances. He seemed like a guy who “got it” and I was excited to find out that he’d be spending time with the class. In fact, I e-mailed the UCAP guys from the back of the aircraft that afternoon to tell them that I was hanging out with James and how fun it was.

Julie Filucci (nee Boatman) also joined us. Julie now works for Cessna, but is perhaps best known for her work with AOPA. She was involved in the project upon which Dan and others were working for AOPA when the DC-3 experienced the gear collapse. She even fabricated a part during the repairs that you can see on the aircraft today. She was scheduled to fly on the Monday after we left, but came in early to hang out with us.

I was first to fly. That meant waking up the ‘three, doing the start, taxiing out, and taking off. A lot more intensive than taking the controls on downwind and doing touch and goes.

I don’t know that the audio tells enough of the story, so I’ll just say this. If you can taxi a DC-3, you can probably fly it. You’re 16 or so feet off the ground and you’re leaning back because the tailwheel is on the ground. It’s hard to see over the nose. And you can only see the wheel on your side. And the aircraft has a lot of momentum once it gets going, so you want to be conservative about how much speed you develop. Plus, the tailwheel is fully free-castering. You can lock it, which is nice for the straightaways, but your butt can feel completely disconnected from the rest of you at times.

Try this at home. Go to a second-floor window in your house. Stand about three feet back from it. Squat down so that your chin is just about level with the windowsill. Now imagine driving your house around the neighborhood. On an icy day. With your patio wanting to swing out from behind you at every turn.

The DC-3 in flight is large in a magnificent and stately way in flight. The DC-3 is large in a cantankerous and intimidating way when taxiing. Add to the fact that the runway at Griffin is surrounded on the approach end of 13 by wetlands and there’s a steep drop-off from the built-up grade of the runway to the wetlands below. The ‘three’s main gear have a width of just under 19 feet. According to the airport master plan, the taxiway width is 25 feet. No pressure.

[Flight Audio 07]

But your reward comes when you pull out onto the approach end of the runway and do your runup and prepare for departure. Dan’s busy as can be running the first officer checklists. A friendly voice from the pattern and the building excitement about getting this 22,000 lb. aircraft off the ground. Then it’s the takeoff run. I’m overclocking my brain, trying to mentally call up the order of commands, the speeds, and the operations and you can hear Dan coaching through liftoff.

[Flight Audio 09]

Day two was all V1 cuts. A V1 cut is a training maneuver in which you simulate an engine failure on takeoff. This is one of the worst things that can happen in any multiengine aircraft because you’re low, you’re out of runway, you’re slow, you’re dirty, and your thrust is asymmetric to say the least.

According to FAR Part 1, V1 means “the maximum speed in the takeoff at which the pilot must take the first action (e.g., apply brakes, reduce thrust, [or] deploy speed brakes) to stop the airplane within the accelerate-stop distance. V1 also means the minimum speed in the takeoff, following a failure of the critical engine . . . at which the pilot can continue the takeoff and achieve the required height above the takeoff surface within the takeoff distance.”

V2 is the takeoff safety speed. FAR Part 1 says that takeoff safety speed is “a referenced airspeed obtained after lift-off at which the required one-engine-inoperative climb performance can be achieved.” Also, according to the design certification of the aircraft, V2 gives you some guarantees about climb performance and maneuverability if you do everything perfectly and the airplane operates exactly as it did on whatever perfect day with whatever perfect pilot flew it for testing.

Both V1 and V2 are 84 KIAS in the DC-3, for reasons that became pretty obvious to me after flying it the first two times. By the way, 84 is also Vr, Vx, and Vxse

There’s a lot happening on takeoff. It’s noisy, you’re on the pedals to keep the aircraft on the centerline, and the shopping mall at the end of the runway is usually getting pretty big in the window. You need a simple and straightforward set of criteria by which to make automatic, hard-and-fast decisions. With the 3,600-foot runway at Griffin or even the 6,400-foot runway at Thomaston, you don’t have a heck of a lot of runway within which to stop if you have an engine failure, so V1 as such is mostly irrelevant.

So it’s all about V2. Trying to go flying with fewer than two motors at less than V2 is, according to the specs, a form of suicide. If you have an engine failure below V2, you accept the shopping mall, chop the throttles, and stand on the brakes. It’s not that you want to visit The GAP. It’s that the airplane will come to rest on the Taco Bell and do so in a much more spectacular way if you don’t.

If you’re better than V2 when you become a large and asymmetric single-engine airplane, it’s usually better to go flying instead.

So, on the takeoff roll, you’re monomaniacal. You advance the throttles and begin the roll with the assumption that you’re going to chop everything and stand on the brakes. Then you hear the FO say “V2” and you see him stick two fingers in front of you where you can see them. At that moment, you forget that the airplane ever had brakes and are monomaniacal about going flying. It’s a quantum thing. Analog thinking will kill you and your passengers and reduce the DC-3 fleet. You’re going shopping or you’re going flying and there is no in between.

The process for the V1 cut in the ‘three is that you rotate at V2 and, shortly thereafter, Dan pulls back the throttle of the engine of which he’s simulating the failure. Your reaction is expected to be immediate and precise. You call out “Engine failure! Gear up!” The first callout tells the FO a little about your mindset and the assumptions upon which you’re operating. It also prepares the FO to get ready to slap your hand out of the way if you do a certain stupid thing. But, most importantly, it causes the FO to raise the gear and get rid of that drag.

Then you have three things to do. You must immediately identify which engine is out, verify that you have the correct engine, and then feather the prob of that engine to get rid of the drag from that windmilling prop. The whole process should take less than ten seconds.

I did my multi training in a Piper Apache 150. It was immediately obvious when the instructor took away an engine. The airplane immediately yawed heavily and it initially took 50 or more pounds of pressure to keep the tail behind me and keep the airplane coordinated. Then I’d look at the ball in the inclinometer for confirmation and put even more pressure on that pedal. There were points on the first day of training when the required pressure was well over 100 pounds and I was in danger of cramping up.

The side opposite the pedal that you press is the side with the dead engine. Dead foot, dead engine. Tom Brady had me take the non-pushing foot off of the pedal and put it on the floor. I added to that by patting the knee of whichever foot was on the floor and saying out loud something like “Dead left foot. Dead left engine.” That’s the “identify” part.

Then you verify that you’ve identified the correct engine. You retard the throttle of the dead engine and, if there’s no change in the flight conditions you’re experiencing, you’ve verified the dead engine. In a V1 cut, you don’t want to actually pull the rest of the dead engine’s power, so you point to the correct throttle lever and say “verify.”

Then you feather, which, in the Apache, means pulling the prop lever all the way back. In the DC-3, this is where the hand-slapping could happen. The DC-3 has auto-feathering props and the auto-feather controls take the form of two large red buttons on the upper middle console. You announce to the FO that you intend to feather by saying something to the effect that “I intend to feather the left engine.” The FO then either concurs and you simulate pushing the button or the FO does not concur and you resolve your differences as quickly as possible.

I like that the auto-feather buttons are where they are. If the pilot flying goofs up and is about to feather the wrong engine, the pilot not flying can reach the pilot flying’s hand and slap it away.

Anyway, that’s the drill.

I had trouble early on as you’ll hear for several reasons. First, although Dan announced on final which engine he was going to fail on the “go” part of the touch-and-go, I deliberately tried to ignore the warning for realism’s sake. I wanted to feel the yaw, see how the ball reacted, and treat it like a real failure.

Second, Dan didn’t pull the throttle back very far and, while there was a definite yaw, it wasn’t as great as I thought it’d be. I’ve always had a pretty dead butt as seat-of-the-pants flying goes and I couldn’t immediately identify the yaw just by feel. And the ball in the ‘three is situated pretty low on the panel where it’s in pretty deep shadow, especially if you’re wearing sunglasses so I didn’t have an instrumental indication upon which to rely.

I have no objection to Dan not pulling the throttle back further. I’m all about ground clearance and not making the training actually dangerous for realism’s sake. But the yaw and rudder pressure not being as great as I expected got me confused and I even had to ask which engine was out.

Here’s audio. We’re on base when Dan announces that we’re going to do a V1 cut.

[Flight Audio 09]

So here we go with the landing and then the first V1 cut. I get as far as the “gear up” command, but that’s about it. I’m sitting there trying to do what made sense in the Apache and having it not work. Ugh.

[Flight Audio 10]

Ever the good instructor, Dan seems to understand what I was doing and fills in some blanks for me.

[Flight Audio 11]

I blow the next one, too. Ugh. Same thing.

I think Dan sensed that I was just plain overloaded. And the solution for overload? A couple of low passes! For whatever reason, the MP3 recorder had cut out during the flight the day before, and I thought that I had missed recording the low approach we did. I had mentioned it to Dan, who filed that bit of information away and picked this ideal time to give me a little distraction and let me gather my wits. We made the crosswind into a teardrop entry into a low approach for 12 and barreled down the runway at 160 KIAS. Then we pulled up and around and got another one down 30.

A Cessna 172 was preparing to depart from 30 and was doing its runup as we came down 12. He was ready to go by the time we had turned around for 30 again, but offered to hold short to see us come back down the runway.

[Flight audio 12]

We did a full stop on the next landing and took on some fuel.

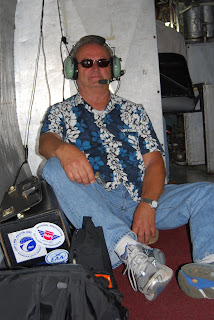

Roland had the left seat for the departure for the next flight and everyone else rotated up the aisle toward the cockpit. I plugged in the recorder where my headset would have gone and just relaxed in the back of the airplane. I left the recorder off to conserve battery. After awhile, Tom, who was rearmost in the corridor, turned around, cupped his mic, lifted his headset, and shouted to me. They had apparently noticed a hydraulic problem in the cockpit and were returning to Griffin. Dan wanted everyone buckled in for the landing. I immediately turned on the recorder, shot a couple of pictures of the cockpit as Dan pumped the hydraulic handle, and then buckled in.

I couldn’t hear what was going on because the recorder was plugged in where my headset would have gone. But I reviewed what happened later with Tom.

Five systems on the DC-3 operate on the hydraulic system www.theaviatornetwork.com/pdf/GTM-13-050130-Hydraulics.pdf. Landing gear, flaps, brakes, cowl flaps, and – of all things – windshield wipers. You have two gages in the cockpit for monitoring hydraulics. A system pressure gage and a landing gear pressure gage. You can hear in the before landing checklist every time that the hydraulic pressure is one of the four things that both the captain and FO have to observe and call out.

A hydraulic problem is actually not much of a problem in the ‘three, at least under the circumstances we experienced. It’s a beautiful VFR day, so no need for the windshield wipers. We ran with the cowl flaps open the whole time to facilitate engine cooling during all of the touch and go activity and we wanted them open anyway. It’s no problem getting the landing gear down. It might be a little exciting getting the gear up without normal hydraulics. This might be a problem if you had to abort the landing and had an engine failure and needed the gear up, but, hey, it’d be a rare thing in the first place and it’s not a perfect world. All things considered, I’d rather have the default state be gear down and locked.

The ‘three lands just fine with no flaps and the only issue there is runway length. We can get her down easily within five or six thousand and it’s probably not a big deal within the 3,600 feet at Griffin.

Which leaves the brakes. That’s really the primary thing in this situation. You need to stop the ‘three on the runway once you get her down. Not a problem with a 10,000-foot runway, but potentially an issue if you’re going to put her down at Griffin with its 3,600 feet of pavement. Griffin is particularly attractive because that’s where Dan’s stock of yellow-tagged parts and other maintenance stuff lives. The manual says that you need 500 PSI landing gear pressure and 500 PSI system pressure for the brakes. Dan verifies that we have 500 or better in both with the hand pump.

[Flight Audio 13]

As you can hear Dan say, the pressure came right back up once we were on the runway, but Dan wasn’t taking any chances. He had a yellow-tagged part as a replacement for the part that was the most likely culprit. He and Roland, with a minor assist from the rest of us, swapped out the part and the A&P came by to inspect the work and certify the aircraft for the next day.

As you can hear Dan say, the pressure came right back up once we were on the runway, but Dan wasn’t taking any chances. He had a yellow-tagged part as a replacement for the part that was the most likely culprit. He and Roland, with a minor assist from the rest of us, swapped out the part and the A&P came by to inspect the work and certify the aircraft for the next day.

It was growing dark when Dan and Roland took the airplane out for a test flight around the patch at Griffin and the rest of us stood by the runway to watch them make a few low approaches and then land.

It provided some quiet time to reflect on my performance that day. I outright blew the V1 cuts. I’m not a longtime multi driver, but I had eight hours of multi within the 40 days prior to going to Griffin with lots of engine failure practice. I should have gotten those. I wasn’t kicking myself, but something approaching that.

I stood on the grass there in Griffin a pretender in many ways. The most junior of the group in most, if not all ways. All airplanes fly under more or less the same parts of the laws of physics. Don’t write me hate mail about lifting bodies and exotic airframes. Things that look like airplanes, no matter their size, pretty much all fly or don’t fly for the same reasons. And most have the majority of their control surfaces in common. Even the greenest student pilot will tell you that all airplanes are fundamentally the same. That’s the paradigm that I took to Griffin with me.

But are you ready to go actually test that out? Are you willing to, say, get into the left seat of an airliner and test that out? With three classmates in back? All of whom are much more experienced than you? All of whom have nothing to do other than watch you fly and listen to you on the intercom? Okay, add a journalist from a widely-read aviation magazine who also happens to be an experienced pilot and knows from pilot skills? Does that ink on your multi rating feel a little wet there in your back pocket yet?

I don’t think there was any snickering going on in back or that anyone actually thought the less of me. But I think that any pilot worth his or her salt studies and prepares and really wants to do well. Like I said: Not kicking myself, but something close to it.

After we got the ‘three parked, we gathered back at the hangar and loaded everyone into crew cars, rental cars, and Dan’s pickup and also loaded in guitars, a banjo, my mandolin, and other implements of destruction and headed for Hangar 19 on Zebulon Road, a couple of miles away. The restaurant has two dining rooms. Looking like a cross between a mobile infantry division and a utility repair crew, we walked in and Dan declared “We’re with the band.”

They set us up at a long table in the other room and we tied on the feedbag. Not too long after ordering, out came the guitars. Dan, James, and Julie started with a couple of tunes and then invited me to grab my mandolin and join in. Dan tuned to my mando (which I had tuned to concert pitch before leaving and, even though it’s smaller, my eight strings trump his six in terms of complexity of tuning) and promptly broke a string. I took the stage and got through a competent rendering of Puff, the Magic Dragon with James on guitar and Julie on vocals while Dan changed out, and then we all got through a couple of numbers before the food came out. Dan had a pretty decent one about a local A&P who was at the table and James busted out a beautiful original ballad of his own before we sat down to eat.

A medium ribeye and some sautéed mushrooms later, the band re-formed and we got into it in earnest. Dan switched to banjo a few tunes in and I took over on his guitar for part of the set. Dan’s a big Eagles fan, so we played plenty of that. Some stuff I didn’t recognize that I presume was Dixie Chicks and a couple of standards. I ventured off into some 12-bar blues to which James improvised lyrics to write – on the spot – the DC-3 Blues. And I played my Carlos Santana version of Stairway to Heaven, which evolved into a bluegrass version of Stairway. They had to start running the vacuum sweeper toward the end, but we just played louder.

[Audio]

I got back to the hangar around 1:00 a.m. Just enough energy to decide not to record an episode and do a blog entry with some of the pictures from the day’s flying. And it was after 2:00 a.m. by the time I got done with the post, packed everything I wouldn’t need in order to fly the next day, and hit the sack. I was pretty well resolved to nail the V1 cuts and needed to be rested in order to do that.

Engine failure, gear up, identify, verify, feather. Engine failure, gear up, identify, verify, feather.

[Flight Audio 14 – ATIS]

Sunday morning came quickly. I got ready and started the coffee and then walked the ramp in a rectangular pattern for awhile doing my callouts.

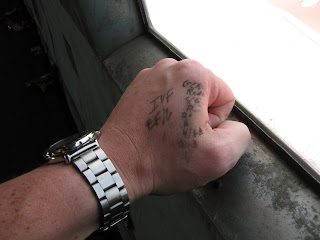

It was pretty warm and I’m a polar bear from the wilds of northern Michigan by disposition. It wouldn’t have mattered much, except that I had taken to writing the pattern litany in abbreviated code on the side of my left hand for quick reference to avoid getting goofed up in the pattern. Today, I was sweating and the ink was smearing on my hand as quickly as I could re-transcribe it.

Everyone showed up around 8:00 and we preflighted and got into the sky as early as possible. Roland had a 4:30 flight direct to Duseldorf and I scheduled my outbound flight around then in order to minimize the number of trips to ATL. So we needed to get Roland and me finished up as soon as possible.

I got the startup and taxi again and felt slightly more competent getting the ‘three out to the hold short line. Dan was on the pedals and the tailwheel, too, to make it an efficient proposition.

[Flight Audio 15]

Dan must have sensed my need for some additional coverage of the V1 cuts – and a little of my frustration from the previous day – because, a few miles after lifting off, he began doing engine failure practice the rest of the way to Peachtree City Falcon Field.

[Flight Audio 16]

So on to the first of several moments of truth. I’m going to have a failure of the right engine on takeoff. That’s going to be left rudder, engine failure, gear up, identify, verify, feather. Left rudder, engine failure, gear up, identify, verify, feather. Gotta nail this.

[Flight Audio 17]

Yeah! That felt good. Alternating between 84 and 120 with the engines out of synch every minute or so is an odd way to go cross-country, but it sure worked for me. I’m wired for V1 cuts. Still learning, mind you, but feeling a lot better and working on improving as opposed to just learning.

So around we go for another one.

On the downwind, the pattern litany is going smoothly and I have enough of it packed into my bandwidth to be able to think ahead to the next V1 cut. And Dan kind of surprises me with a compliment.

[Flight Audio 18]

It might have sounded a little like I was blowing Dan off. I kind of wished that I had thanked him more clearly for that. He really didn’t have to say it. And I can’t begin to say how much that meant to me. But I know he’ll understand when he listens to this that my subconscious had already focused the rest of my brain on the next V1 cut and decided that there wasn’t any bandwidth left over to switch gears and give full attention to the “thank you” that Dan deserved. I think I had made the decision at some level that the best “thank you” would be a well-executed V1 cut. And I guess that was right.

Another competent V1 cut on the next landing. I’m looking at the throttle quadrant a bit more than I should in the process and Dan gives me some more pointers on the where to focus and the proper tempo of the procedure, but a decent V1 cut just the same. We do another couple of cuts on an extended departure leg to make sure that I’ve got it fine tuned. Then it’s a right turn to rejoin the traffic pattern.

On base, right after we go to full flaps and take care of final items, Dan announces that Roland is up next and that it’s my last landing. It’s bittersweet. I think I’ve got the V1 cut boogeyman reasonably at bay and I want to nail this last landing. But I want to keep my eyes open and really take in this experience from the left seat one more time. It’s going to be a long time before I fly a DC-3 again. Maybe never. One last look at the runway crawling toward me, the sleepy Georgia woods and hills spreading out into the distance. The wind eddying outside the window next to me. The guys in the hallway behind me watching and sharing the experience. And Dan in the right seat orchestrating the proceedings with an easy manner and studied hand.

Then it’s all focus on – as ever – flying the airplane.

[Flight Audio 19]

As we fueled up and took a break at Peachtree City Falcon Field, we met with the FAA inspector and did the paperwork. I walked back out to the airplane with a fresh new temporary airman certificate – My second in just over a month. It says “DC-3” on it. And will for as long as I hold that certificate.

No matter that it’s second in command. That’s plenty for me. 2.8 hours, 14 takeoffs, and 13 landings. In an icon of aviation.

It’s a rating that’ll make even a 747 captain jealous. Not that I’m a better pilot than a 747 driver. But I am different and I’ve have had an experience that few people alive have had. And that number is declining. But, for now, the legacy of the DC-3 lives on and burns bright in one more heart. Mine.

It all comes back to my first question. What’s general aviation really all about?

It’s the challenge of learning to fly an airliner. From reading the manuals on the patio in Michigan to actually preflighting, taxiing, and flying the airplane across the Georgia countryside as the specs, drawings, and procedures melt from the page and become as real as the yoke and the throttles in your hands. And going from being a 185-hour single-engine driver through a whirlwind of training, ratings, and endorsements that culminate in something that few private pilots ever achieve.

It’s about sharing a learning experience with a class whose members come from across nine time zones. Tom, Roland, Gerrit, and me. It’s about James Wynbrandt showing up as a writer on assignment who could have been a mere spectator, but who lived and breathed the experience with the rest of us. And when he got his turn at the controls (yeah, he got a low pass and a landing), he calmly sat down in the left seat and picked up the callouts and procedures like it was just another day in the DC-3 for him.

It’s about Julie returning to fly the airplane that bears the part she fabricated and that probably means more to her than the rest of us really understand.

It’s certainly about Dan, who truly loves this airplane and loves putting other people in the left seat to experience it.

It’s about three or four people standing or crouching in the walkway behind the cockpit observing the training and preparing to rotate up to the left seat and it’s about walking into a restaurant with guitars, a banjo, and a mandolin and taking over the place for a couple of hours playing whatever comes to mind.

It’s about the way that the nose of a DC-3 angles up against the horizon as it sits on the ramp and the unmistakable and iconic silhouette it makes against the sky as it flies overhead. It’s living and breathing history that inspires even non-aviators who can’t identify the make or model or anything else about it but know, somehow, that that silhouette is special.

And it’s about the Big Dream. Which, after all, is really just shorthand for everything I’ve just said. It’s anything that makes you realize that you’re a little different after having had the experience.

If, someday, I take advantage of an empty pattern at an uncontrolled airport somewhere to again key the mic and say, “the DC-3 is on left base for three-zero,” you’ll just have to forgive me.

Many thanks to Dan Gryder and Gryder Networks for putting me up in the crew quarters, making available a great crew car, buying dinners, letting me sit in with the band, and maintaining a really wonderful airplane.

Thanks to the gracious and studious James Wynbrandt for not laughing or putting palm to forehead at times when it would have been appropriate.

I think we all owe a tip of the hat to Herpa, as well, for its consistent and generous support of this flying icon. Not just those of us who have flown her. But for everyone who gets to look up and see history in the skies above Florida, Georgia, Wisconsin, and all points in between.

The musical theme for this episode is “Cold” from the ever-in-development “Songs from the Sheffield – The First Folk Music of the Journey to Mars and Back.” Yours truly on guitar, mandolin, and xaphoon (an approximately foot-long reed instrument sometimes called the “pocket sax”).

Scott Canizzaro produced and remixed the Airspeed main theme music. You can reach him at nycmixer@mac.com or http://www.scottcannizzaro.com/.

Thanks to Aero-News for permission to use the outtake from the ANN Special Feature of December 11, 2007. .

Airspeed is brought to you by Fat Jimmy’s hand-cut steaks, seafood, and barbecue on US-127 in Addision, Michigan. Open for lunch and dinner Tuesday through Sunday. 517-541-5603.

And by Kenzoil, a flavorful blend of extra virgin olive oil, fresh basil, garlic, and spices, available in the cooler section of fine stores everywhere in southeast Michigan and at Whole Foods markets throughout the Midwest. Kenzoil. Boldly flavorful! www.kenzoil.com.

Can your aviation podcast claim preferred status at a great barbecue joint and the kitchen ninja of condiments? I think not!

Ed Robertson! Alex Lifeson! Claim your rightful place as a guest on Airspeed. E-mail me!

You can reach us here at airspeed at steve@airspeedonline.com and http://www.airspeedonline.com/, and follow me on Twitter as StephenForce.